Aquolac Paints

Coloring your life

Or Call: 9810 044 568

Interior & Exterior

Concrete Admixture

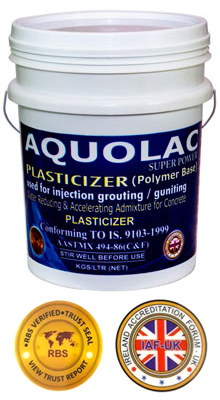

Aquolac Super Power Plasticizer

Polymer Base Plasticizer

Aquolac Super Power Plasticizer is a polymer base plasticizer. Used for injection grouting and guniting. It is a water reducing agent and accelerator. Due to its flexible nature and free flow quality when mix with cement it fills all the capillaries in the walls and hence AQUOLAC SUPER POWER PLASTICIZER is the perfect material for grouting and guniting. It is specially used for waterproofing in basement.

Fill the below form for more information on Aquolac Super Power Plasticizer and we will get in touch with you soon!

Our Story

High Quality Residential & Commercial Painting Since 1959

AQUOLAC group is one of the Largest Paint Groups engaged in the manufacturing of Paints and its allied products. The Group was established in the year 1959 having its Corporate Office at New Delhi and marketing network throughout India. The product range covers a wide spectrum of Decorative, Protective Paints, Construction Chemical and Water proofing Compounds. To keep in tune with the latest technology in the world, Aquolac had entered into world class new generation durable range of Aquatex Textured Wall Coating finishes of which we were the pioneers and are catering to the Indian as well as the export market. The product’s have been approved and are being used by various Government/ Semi- Government departments, renowned Architects/Consultants, Private and Public sector undertakings.

Our gallery

Product Application

Testimonials

Please fill the form and share your requirements,

our experts will get in touch with you to help you in your project.

Email us and share your requirements

Or Call: +919910073124